Ammonia is a critical component in various industrial processes, particularly in refrigeration systems, fertilizers, and chemical manufacturing. While its uses are invaluable, ammonia can pose significant risks when leaks occur. An ammonia leak can lead to serious health, environmental, and operational consequences. This article explores the causes of ammonia leaks, their potential dangers, and how to prevent and manage them effectively.

What Is an Ammonia Leak?

Ammonia (NH₃) is a colorless gas with a pungent odor. It is highly soluble in water and widely used in industrial and commercial applications due to its chemical properties.

Key Applications of Ammonia

- Refrigeration Systems

Ammonia is commonly used as a refrigerant in industrial systems due to its excellent heat transfer capabilities. - Fertilizers

Ammonia is a primary ingredient in nitrogen-based fertilizers, crucial for agricultural productivity. - Chemical Manufacturing

It serves as a precursor in the production of explosives, plastics, and cleaning agents. - Water Treatment

Ammonia is also employed to neutralize acidity in water and improve quality.

While ammonia is effective in these applications, its volatile nature demands careful handling and robust safety measures.

Common Causes of Ammonia Leaks

Ammonia leaks can occur due to several factors, ranging from equipment failure to human error. Identifying these causes is crucial for implementing effective prevention strategies.

1. Corrosion of Equipment

Over time, pipes, valves, and tanks used in ammonia systems can corrode, especially if maintenance schedules are not followed. Leaks occur when corrosion destroys the equipment's structural integrity.

2. Poor Maintenance

Neglecting routine inspections and repairs can result in undetected wear and tear. Faulty gaskets, seals, or worn-out components often become sources of leaks.

3. Human Error

Improper handling of ammonia systems, including incorrect installation or mishandling during maintenance, can increase the risk of leaks. Failing to follow safety protocols also contributes significantly.

4. Overpressure in Systems

Excessive pressure within ammonia systems due to operational issues or temperature fluctuations can cause ruptures or leaks.

5. Accidental Damage

External impacts, such as collisions with machinery or tools, can damage pipes and containers, causing leaks.

6. Aging Infrastructure

Old ammonia systems may not comply with modern safety standards, making them more prone to leaks.

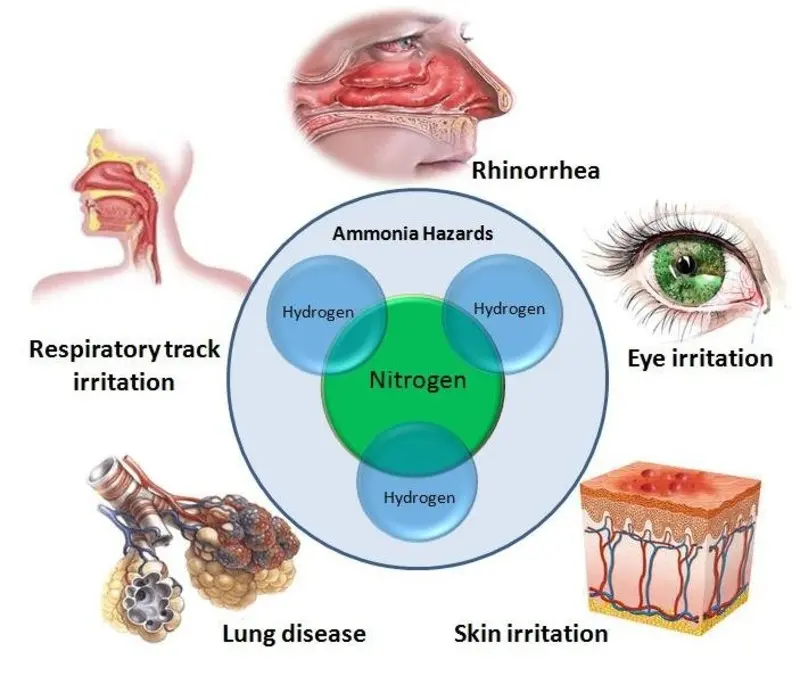

Risks of Ammonia Exposure to Health

Ammonia is a toxic gas, and exposure to leaks can have serious health implications, depending on the concentration and duration.

Acute Health Effects

- Low-Level Exposure:

May irritate the eyes, nose, throat, and respiratory system, with symptoms such as coughing and shortness of breath. - High-Level Exposure:

Can lead to severe skin and respiratory tract burns, difficulty breathing, chest pain, or critical conditions like pulmonary edema.

It is essential to comprehend these dangers to prevent and respond effectively.

Chronic Health Effects

Prolonged exposure to low concentrations of ammonia may lead to respiratory issues, reduced lung function, and sensitivity to irritants.

Effects of Ammonia Leaks on the Environment

Ammonia leaks can have devastating effects on the environment, especially aquatic ecosystems. When ammonia enters water bodies, it can cause the following:

- Water Pollution

Ammonia is toxic to aquatic life, leading to fish kills and damage to aquatic ecosystems. - Soil Contamination

Leaked ammonia can alter soil pH levels, affecting plant growth. - Air Pollution

Ammonia gas released into the atmosphere contributes to air quality degradation.

How to Detect Ammonia Leaks

Early detection of ammonia leaks is crucial for minimizing risks. Modern technology and proactive measures can help identify leaks promptly.

1. Odor Detection

Ammonia has a strong, distinct smell that can serve as the first indication of a leak. However, relying solely on odor is risky, especially in large or ventilated areas.

2. Ammonia Detectors

Specialized sensors and alarms can detect ammonia concentrations in the air, providing immediate alerts for action.

3. Visual Inspection

Frost buildup around pipes, valves, or joints may indicate an ammonia leak. Additionally, bubbling in wet areas or condensation patterns may suggest leakage.

4. Maintenance and Inspections

Regularly scheduled inspections of equipment and systems can identify potential issues before they lead to leaks.

Handling Ammonia Leaks

When an ammonia leak occurs, swift and effective action is essential to protect people, property, and the environment.

1. Emergency Response Protocols

Every facility handling ammonia should have an emergency response plan in place. This includes evacuation procedures, emergency contact numbers, and designated safety zones.

2. Personal Protective Equipment (PPE)

Responders must wear appropriate PPE, such as chemical-resistant suits, gloves, goggles, and respirators, to minimize exposure risks.

3. Ventilation

Ensure proper ventilation to disperse ammonia gas and reduce concentration levels in the affected area.

4. Neutralization

Spilled liquid ammonia can be neutralized using weak acid solutions, such as vinegar, to reduce its corrosive effects.

5. Professional Cleanup

Engage certified professionals to assess and repair the leak, ensuring compliance with safety regulations.

Preventing Ammonia Leaks

Preventive measures are the best way to avoid the risks associated with ammonia leaks. Here are some best practices:

1. Regular Maintenance

Conduct regular inspections and maintenance of ammonia systems, including checking for corrosion, wear, and pressure stability.

2. Employee Training

Train employees on the proper handling of ammonia, emergency response procedures, and the importance of safety protocols.

3. Install Leak Detection Systems

Invest in advanced ammonia detection systems to identify leaks early and prevent escalation.

4. Upgrade Aging Infrastructure

Replace outdated equipment and systems with modern, compliant alternatives to reduce the risk of failure.

5. Follow Regulatory Standards

Adhere to local and international safety regulations for ammonia storage, transportation, and usage.

Regulatory Guidelines and Compliance

Various organizations provide guidelines and regulations for handling ammonia leaks safely:

- Occupational Safety and Health Administration (OSHA): Defines workplace exposure limits and enforces safety protocols to protect employees.

- Environmental Protection Agency (EPA): Oversees ammonia emissions and implements environmental safety measures.

- American National Standards Institute (ANSI): Develops industry standards for ammonia refrigeration systems and operational best practices.

Conduct to these regulations mitigates risks and promotes a secure working environment.

Conclusion

Ammonia is a valuable chemical in numerous industries, but its potential risks cannot be overlooked. Understanding the causes of ammonia leaks and implementing robust detection, prevention, and response measures are essential for safeguarding health, property, and the environment. By prioritizing safety and adhering to regulatory standards, facilities can harness the benefits of ammonia while minimizing its dangers.

Related Articles

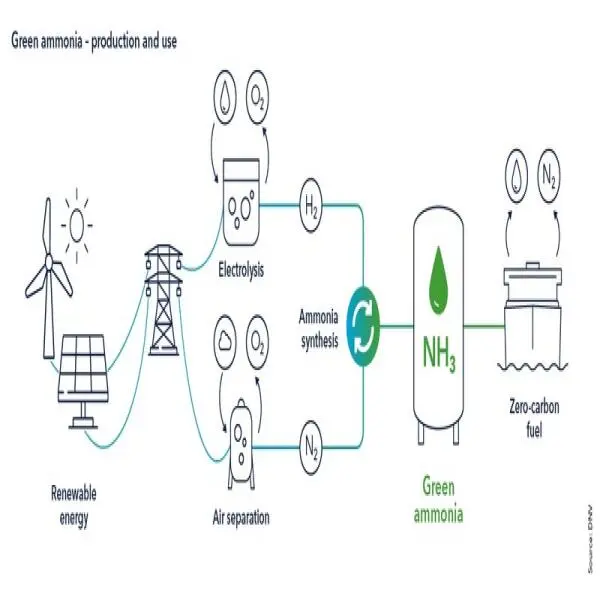

How Ammonia Fuel Works and Its Role in Renewable Energy

With the growing demand for alternatives, ammonia fuel is emerging as a promising standout in the ...

The Role of Algae in Aquatic Environments

Algae play an essential role in maintaining the balance and health of aquatic ecosystems. Often ...

Why is Bacteria Water Treatment Important? How Bacteria Clean Our Water

Water treatment is a cornerstone of environmental sustainability, essential for ensuring safe water ...

What Are the Key Factors Affecting Aquaculture Water Quality?

Aquaculture is a rapidly expanding industry and plays a vital role in providing a sustainable source ...

The Impact of Heavy Metals on Aquaculture Water: Challenges and Solutions

Aquaculture water is an indispensable resource in ensuring the health and sustainability of aquatic ...

What is Pond Water Alkalinity and Why Does it Matter?

As a pond owner, ensuring the health and well-being of your Koi and Goldfish requires a keen ...