Water is essential for life, yet access to clean and safe water remains a significant challenge globally. With increasing industrialization and urbanization, water sources are becoming increasingly contaminated with various pollutants, including industrial effluents, sewage, and other harmful substances. This is where the Polyaluminium Chloride or PAC for water treatment solution comes into play.

What is PAC Chemical? The Role of PAC in Wastewater Treatment

Understanding the specifics of PAC and its function in water treatment is crucial for appreciating its widespread use and effectiveness. In this section, we will delve into what PAC chemical is, its unique properties, and how it plays a vital role in treating wastewater.

What is PAC Chemical?

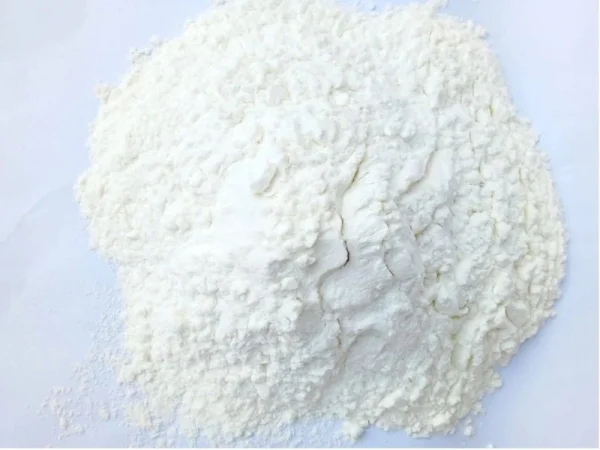

PAC (Poly Aluminium Chloride) is a type of aluminum sulfate that exists in polymer form. Its molecular formula is [Al2(OH)nCl6-n]m. Currently, PAC is produced in large quantities and widely used in advanced countries to replace aluminum sulfate in wastewater treatment, especially for highly polluted wastewater.

What is PAC Chemical?

Function of PAC in Water Treatment

PAC has a better ability to remove dissolved and undissolved organic substances and heavy metals compared to aluminum sulfate. This helps increase the clarity of the water, as PAC has a good color absorption ability, making it highly effective in wastewater treatment and various industries such as textile dyeing and paper production.

PAC for water treatment works best in pH conditions of around 6.5 – 8.5. As a result, heavy metals precipitate and settle at the bottom of the water basin, facilitating the wastewater treatment process.

The Pros and Cons of PAC

PAC chemicals plays a crucial role in water treatment. However, understanding its advantages and limitations in practical applications is essential. Here are some pros and cons of PAC for water treatment:

Advantages:

- Highly effective in removing organic substances, heavy metals, bacteria, and viruses from water.

- Can operate well within a wide pH range, from 5 to 9.

- Cost-effective as it requires only a low dosage.

- Environmentally friendly due to its absence of toxic substances.

Disadvantages:

- May cause excessive precipitation, leading to clogging of water treatment equipment.

- Can lower the pH of water after treatment, necessitating pH adjustment using alkaline substances.

- Direct contact may cause skin and eye irritation.

Therefore, when using PAC for water treatment, it is crucial to adhere to occupational safety and environmental protection regulations. Selecting the appropriate type of PAC, determining the right dosage, and checking the water quality after treatment are essential steps.

PAC for water treatment requires only a low dosage

How to Prepare PAC for Water Treatment

PAC for water treatment can be in solid or liquid form. For solid PAC for water treatment, it must be prepared into a 5% - 10% solution before adding it to the wastewater. Here is the preparation method for PAC solution:

- Fill the container with water up to half of its capacity.

- Gradually add PAC powder into the container at a ratio of 5 - 10 kg of PAC powder per 100 liters of water.

- Stir the PAC solution until fully dissolved.

- Continue filling the container with water to the desired level.

- Turn on the chemical pump to inject the PAC solution into the water source needing treatment.

For liquid PAC for water treatment, it can be used directly or diluted into a 5% - 10% solution depending on requirements. Follow these preparation method bellow:

- Fill the container with water up to half of its capacity.

- Gradually add liquid PAC into the container at a ratio of 5 - 10 liters of liquid PAC per 100 liters of water.

- Stir the PAC solution until fully dissolved.

- Continue filling the container with water to the desired level.

- Turn on the chemical pump to inject the PAC solution into the water source needing treatment.

Note: The diluted PAC for water treatment solution should be used within 4 - 8 hours to avoid losing effectiveness.

PAC Dosage for Various Types of Wastewater

The PAC dosage will depend on the characteristics and pollution levels of different wastewater types. Below are some reference dosages for various wastewater types:

| Application Field | Unit kg/1000m³ water |

| Domestic water | 2.5 ~ 25 |

| Urban wastewater | 15 ~ 50 |

| Metallurgical wastewater | 20 ~ 150 |

| Printing and dyeing wastewater | 100 ~ 300 |

| Paint wastewater | 100 ~ 300 |

| Food industry wastewater | 50 ~ 150 |

| Emulsion wastewater | 50 ~ 200 |

| Industrial water | 2.5 ~ 25 |

| Electroplating wastewater | 20 ~ 100 |

| Paper industry wastewater | 50 ~ 300 |

| Wastewater from Bleaching and Dyeing | 100 ~ 300 |

| Tanning wastewater | 100 ~ 300 |

| Chemical wastewater | 50 ~ 100 |

| Coal washing wastewater | 30 ~ 100 |

However, the most accurate and appropriate dosage can only be determined through direct testing with the specific water source needing treatment. Here's how to determine it:

- Take 800 ml of wastewater into a glass cup.

- Add a certain amount of diluted PAC into the cup and stir well.

- Observe the sedimentation ability of PAC.

- Continuously repeat the experiments with different dosages.

- Find the appropriate dosage for the wastewater source to be treated.

Notes: When Preparing PAC for water Treatment

- Do not overdose PAC, as it may cause the re-stabilization of colloidal particles, reducing treatment efficiency.

- Avoid using PAC with other chemicals that are strongly acidic or alkaline, as unwanted chemical reactions may occur.

- Avoid direct contact of PAC with skin or eyes, as it may cause irritation or burns. If exposed, rinse thoroughly with water and seek medical advice.

- Avoid contact of PAC with metals prone to corrosion, as PAC contains Chloride.

Why PAC is Gradually Replacing Aluminum Sulfate?

With the results and quality of treated wastewater using PAC chemicals, aluminum sulfate is being gradually phased out and less used at present. PAC for water treatment has several advantages over aluminum sulfate, including:

Main advantages of PAC for Water Treatment

- PAC increases the coagulation effect in water, prolonging the filtration and sedimentation cycle, ensuring the removal of suspended organic substances and floating solids.

- PAC for water treatment contains a small amount of aluminum chloride, which reacts with alkaline substances. Therefore, when dissolved in water, PAC has lower acidity, and the pH level does not drop suddenly, automatically adjusting to a suitable level. This saves costs on purchasing chemicals for pH adjustment and dosing pumps needed for neutralizing water with aluminum sulfate.

- The optimal pH range for PAC coagulation is around 6.5 – 8.5. At this pH range, heavy metal ions precipitate and settle at the bottom of the tank or adhere to the coagulant particles, forming large flocculated sludge floating on the water surface.

- Using PAC coagulant chemicals reduces equipment corrosion.

- PAC for water treatment is packaged in sealed bags or plastic cans, making transportation, storage, and dosing easier compared to aluminum sulfate.

- PAC can be dissolved in any wastewater ratio.

- PAC provides higher sedimentation efficiency compared to aluminum sulfate, up to 4-5 times.

- Coagulation occurs quickly, with flocs forming within 1-2 hours of chemical addition.

- PAC requires a low dosage, produces large flocs, and is easy to settle.

- Simple and quick to use, often without needing additional support equipment or chemicals unless dealing with particularly challenging water sources.

PAC can be dissolved in any wastewater ratio

Other advantages of PAC for Water Treatment

When dissolving PAC, it creates Al13 polymer particles that neutralize the charge of colloidal particles, causing strong coagulation. The hydrolysis rate is also much slower than Al3+, significantly extending the presence of colloidal particles in water without consuming too much PAC, making it cost-effective.

PAC’s ability to stabilize pH levels is also 2-3 times greater than aluminum sulfate, making coagulation easier, more applicable to wastewater treatment projects, and forming larger flocs that are easier to remove. This supports subsequent processing stages efficiently.

Conclusion

PAC is currently among the top chemicals for effective wastewater treatment services on the market. With its superior advantages and high application results, PAC is becoming increasingly favored by the public and wastewater treatment units. However, to obtain high-quality PAC for water treatment, it is essential to purchase from reputable sources with clear origins to avoid substandard products.

Obtain high-quality PAC from Dong A Chemical

If you are unsure where to buy quality PAC for Water Treatment at reasonable prices, contact Dong A. We specialize in distributing genuine PAC chemicals with clear origins, ensuring customers’ peace of mind.

Contact Information:

- Hotline: (+84) 985797941

- Email: export@dongachem.vn

- Website: dongachem.vn

- Address: Khu 9, Phong Chau Town, Phu Ninh District, Phu Tho Province, Vietnam

Related Articles

How Many Chlorine Tablets for Your Pool? A Step-by-Step Guide to Proper Dosage and Maintenance

One of the most crucial components in keeping your pool water crystal clear and free from harmful ...

Finding the Best Chlorine for Your Pool: A Comprehensive Guide

Chlorine is the backbone of pool sanitation, responsible for killing harmful bacteria, viruses, and ...

Exploring the Different Types of Chlorine Used in Water Treatment

Water treatment and disinfection are essential for maintaining the safety and quality of our water ...

Is It Safe to Touch PAC Chemicals with Bare Hands?

If you work in the water treatment industry, you've likely heard of PAC chemicals . As known, this ...

Liquid Chlorine vs Tablets - Which is Better?

Maintaining a clean and safe swimming pool is crucial for an enjoyable and healthy swimming ...

PAC Powder: The Versatile Solution for Water Treatment

PAC powder , short for Poly Aluminium Chloride powder, has emerged as a game-changer in the field of ...